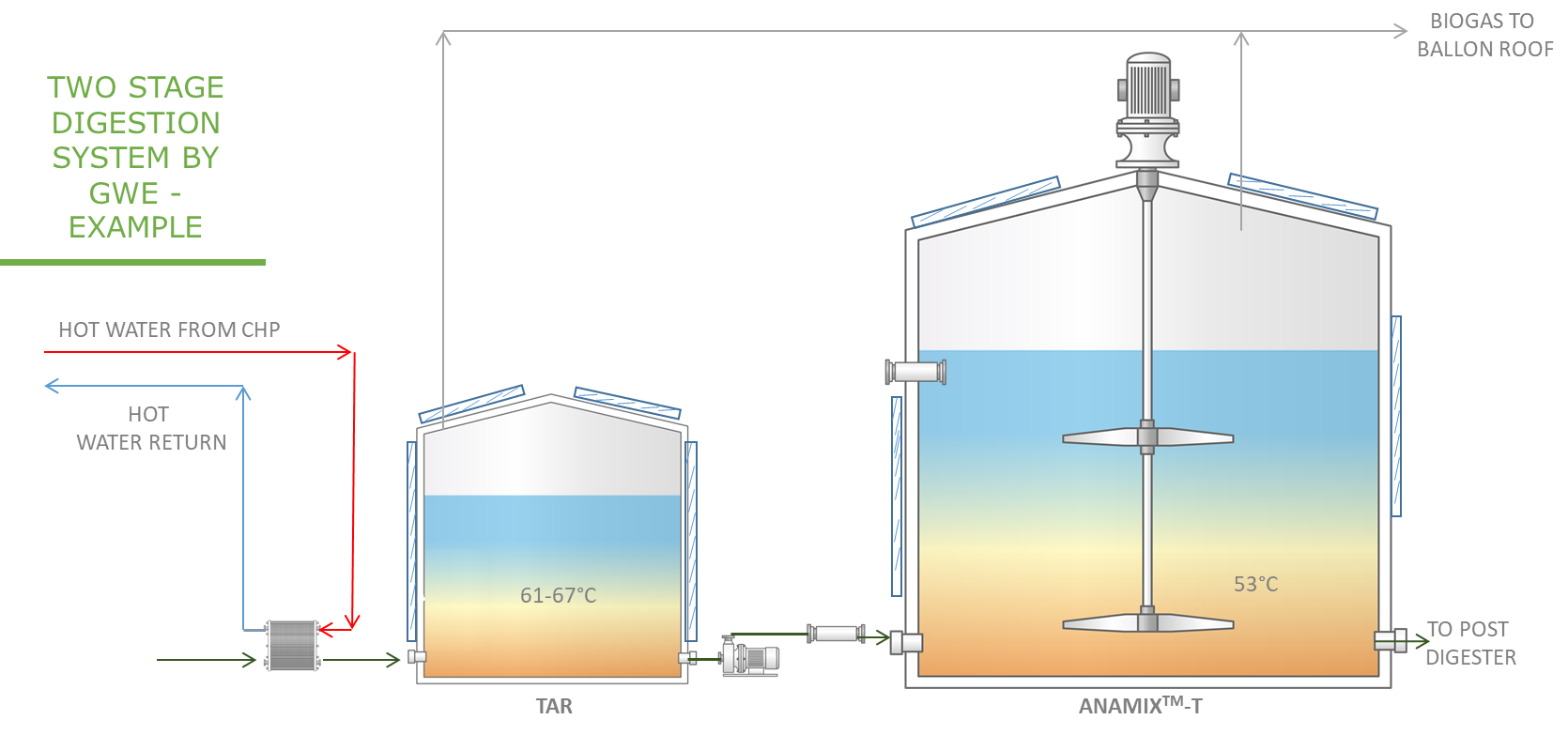

The suitably pre-treated and blended organic waste slurry is then transferred at a controlled rate into GWE ANAMIX™ digesters. As solids digestion occurs twice as fast at high temperatures than at low temperatures, thermophilic digestion (50–55°C) is usually preferred. The exception to that are applications with organic wastes high in nitrogen, which can require an intermediate temperature or mesophilic digestion at 35-40°C.

Our standard ANAMIX™ digesters, use energy-efficient and low-maintenance mechanical mixing systems in the form of a large top entry mixer and are available in sizes up to 3.2 MG (12,000 m3). Depending on the application, optional equipment might be required to ensure optimal performance. Possible extras include a foam breaker fan, a scum control system or a (sloped) bottom grit trap.

Customized reactor configurations can also be utilized depending on the customer’s needs and local situation.

The RAPTOR™ tanks are always fully insulated and heated externally, by recycling the digester contents through a unique heat exchanger.

Depending on the type and characteristics of the organic waste applied as feedstock, biogas production rates of up to 6.3 Nm3/day of biogas for every cubic meter of digester volume can be obtained in RAPTOR™ plants.

The ANAMIX™ reactor digestate is usually treated in a centrifuge or sludge press for separation of the nondigestible solids (wet sludge cake), which is ideal as fertilizer in agriculture. Sludge cake drying and pelletizing systems are also available on request if further processing is needed.

The remaining liquid digestate constitutes a small wastewater stream and is often managed by recycling to add to the fresh solid waste in the pretreatment stages, recycled to a TAR pretreatment unit, disposed of in a conventional aerobic wastewater treatment plant prior to sewer discharge, or treated in a complete, dedicated zero-discharge wastewater treatment plant that includes RO-concentration and evaporation. For agricultural RAPTOR™ plants, the digestate is usually stored and spread on fields in the appropriate season as liquid fertilizer.

How can RAPTOR™ benefit communities?

The RAPTOR™ process for OFMSW and source-separated organics (SSO)

RAPTOR™ efficiently converts the Organic Fraction of Municipal Solid Waste (OFMSW) and/or Source Separated Organics (SSO) into valuable electricity and heat, or renewable natural gas (RNG).

Diversion of organic waste from local communities and businesses from the landfill helps to prolong the life of such disposal sites, reducing the need for new ones. As it is a closed process, it also provides a greater reduction in greenhouse gas generation than a landfill or composting operation, neither of which have control of methane and carbon dioxide emissions.

- The overall sustainability of the region is improved after a renewable energy source like RAPTOR™ is developed;

- RAPTOR® anaerobic digestion contributes to significant greenhouse gases (GHG) reduction and fossil fuel savings;

- It is a complete organic waste-to-energy plant, including management of all end products and residuals, allowing for easy implementation in complete partnership with GWE;

- GWE control software allows for remote monitoring of the facility for smooth operation and uninterrupted electricity delivery, rain or shine, day or night. Other renewable energy methods like wind or solar are impacted by time of day, weather, and other factors that have no impact on RAPTOR®;

- System digestate can be used as an agricultural fertilizer or compost, providing additional value from the waste.

Biogas Utilization–Green Power and Vehicle Fuel from the RAPTOR™ Process

Biogas generated in the RAPTOR® process is desulphurized and partially dried, using GWE’s SULFURIX™ scrubbers and GASODRIX™ dryer systems, and typically used in a Combined Heat and Power (CHP) unit for green power generation, or further treated to remove carbon dioxide and upgraded to create renewable natural gas (RNG).

Government aid under the form of grants, soft loans or regulated minimum prices for power from renewable sources sold to the public grid, are often available from local, regional, and federal sources, to make power generation or RNG production an economically attractive application for the biogas. GWE can often assist with the identification of and development of applications for such incentives.

Industries and applications: Food waste (source-separated organics); agro-industry residues (beet pulp, tapioca pulp, sugar beet waste, onion processing wastes, vegetable/potato waste); industrial residues (brewery waste, food processing wastes, paper mill sludge); energy crops (corn silage, various grasses, Algae).